info@tetos.co.kr

Contact Us

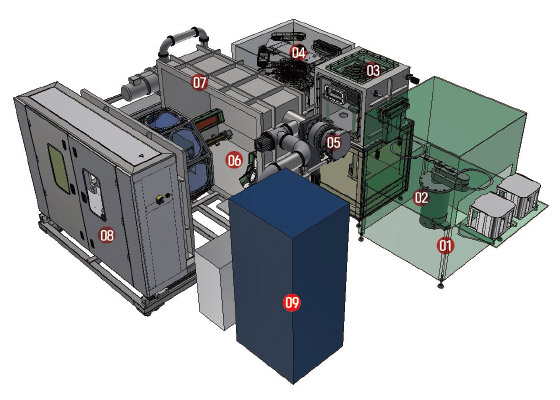

Basic Configuration of Sputter (1Chamber)

— Sputtering Chamber + Carrier L/UL(Vacuum/Standby) + Baking Chamber + Cassette L/UL

| 01. Cassette L/UL 02. Carrier L/UL Robot 03. Baking Chamber 04. Carrier L/UL Vacuum Robot 05. High Vacuum Pump 06. Carrier Mounted Rotation Jig 07. Sputtering maintenance UT/Door 08. Sputtering Chamber 09. Medium Vacuum Pump/Chiller |

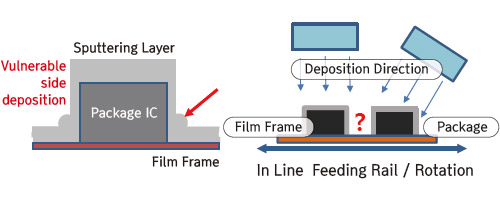

Comparison of Batch Rotation Sputtering Process

ㆍExisting Inline / Cluster Type

Multi Chamber Sputtering (3~5Chamber)

Since deposition thickness is thinner on the side than on the top of the chip and the deposition thickness becomes thick on the film side,

deposition film peeling-off or burr occur on the PKG corner parts in Pick * Place process.

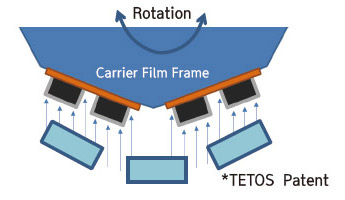

ㆍTETOS Two-way Rotation Deposition Type

1 Chamber Rotation Sputtering

– Angle of 5~ 30˚ is generated during deposition with two-way rotation of

Carrier, which is advantageous for Package side

– Deposition thickness on the Top and the side is relatively uniform.

– Less falling of Corner deposition or less adhesion of deposition film.

– Short cleaning time and target replacement time with 1 chamber

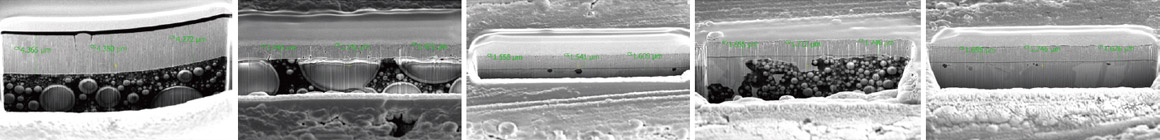

Package EMI Shielding TEST Result

ㆍFIB Image of Other Companies(x10,000)

ㆍTETOS FIB Image(x10,000)

Other Services

-

Plastic Cored Solder Ball

Plastic Cored Solder Ball — Solder ball for semiconductor packaging(Plastic Cored Solder Ball) — Compared to competitors’ multi-layered plated films, manufacturing method

-

Screening/Radiator Film

Screening/Radiator Film — Shielding/heat radiation film deposition — Replace traditional plating with sputtering. Gain quality and price competitiveness by diversifying and simplifying